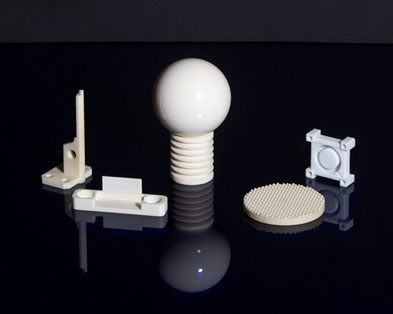

Products & Material Capabilities

Products

Modern Ceramics Manufacturing, Inc. specializes in the fabrication of precision ceramic, plastic, and metal components. Product size ranges from small parts less than 0.1” in length or diameter to 25” in diameter parts x 45” long.

Products examples include fluid handling components for control valves and precision dispensing pumps. We produce parts used in medical, instrumentation, semiconductor, laser, microwave, and oil and gas equipment, such as rings, nozzles, shafts, seals, seats, masks, end effectors, and dies to name a few. We produce thousands of parts across a broad spectrum of industries to exact customer drawings and specifications while maintaining confidentiality through non-disclosure agreements.

Material Capabilities

We maintain in stock a wide size variety of as-fired 96%-99.8% alumina isopressed rods, tubes, rings, and plates. By maintaining as-fired blanks in stock, we greatly reduced material lead times and quickly begin CNC or manual ceramic grinding when a purchase order is received to achieve our exceptional standard lead time of 3-4 weeks. Ask about our industry leading expedited lead times from a few days to a few weeks for simple to complex prototypes and production parts. Modern Ceramics Manufacturing sets the industry standard for producing high-precision, high-quality industrial alumina ceramic components in a timely manner. Challenge us with your alumina ceramic component project today.

Other capabilities are available through in-house and industry partners: dry pressing, extrusion, green machining, injection molding, metallization, brazing, glass bonding, coatings, and surface treatments.

Finishing

Precision machining capabilities include:

- CNC grinding (mills, lathes)

- CNC machining (mills, lathes)

- Surface grinding

- Centerless grinding

- Lapping & polishing

- Honing

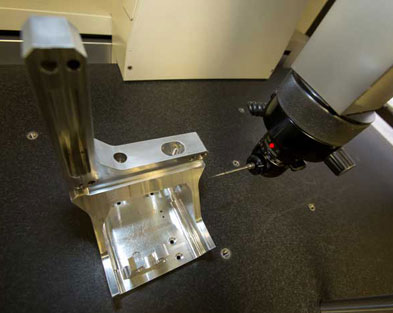

Assembly, Post-Fabrication, & Inspection

Parts are cleaned in a Class 100 clean room when required and assembled and packaged in a Class 1000 clean room. Parts and assemblies are identified through laser marking, stamping, and scribing. Parts and assemblies are inspected in a certified inspection room with multiple CMM’s (Coordinate Measurement Machines) and various calibrated inspection equipment. Our engineers and highly skilled workforce are equipped with the latest ceramic processing and measurement equipment. We manufacture to customer drawings in a total quality environment.

Utilizing CNC coordinate measuring machines, electronic gauging, and our large inventory of general inspection tooling, each part is thoroughly scrutinized. All of our equipment is monitored and maintained through a full-gauge recall and calibration program, ensuring accuracy and precision.

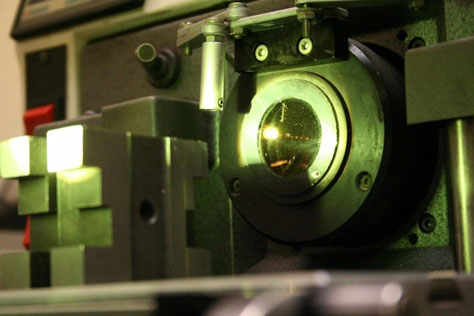

Example of optical comparator set-up

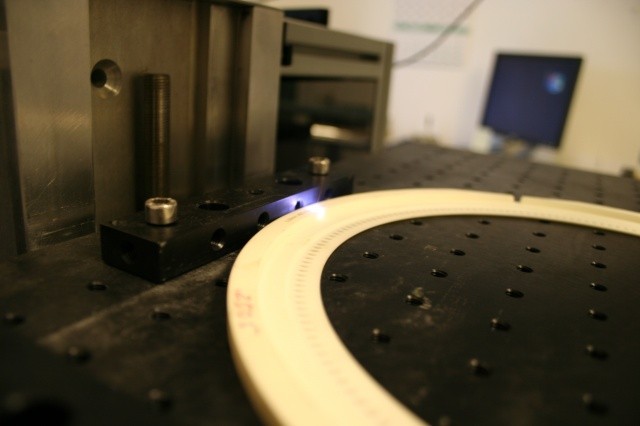

Example of a ceramic clamp ring being inspected on a CMM (Coordinate Measurement Machine)

All parts are fully documented during manufacturing to provide complete traceability. Furthermore, ceramic parts are laser marked with a date code and unique serial number to provide traceability by the customer.Inspection documents, material and ROHS certifications are available upon request.

Laser Marking

Core Competency

Modern Ceramics' core competency is the precision fabrication of alumina and zirconia ceramic components and assemblies. We are skilled at grinding threads in ceramic parts, installing helicoils, and press fitting ceramic-to-metal assemblies. Many of our customers request toll grinding services and we will work with customer supplied materials. Our application engineers and skilled machinists can assist with part design and modifications to enhance part performance.