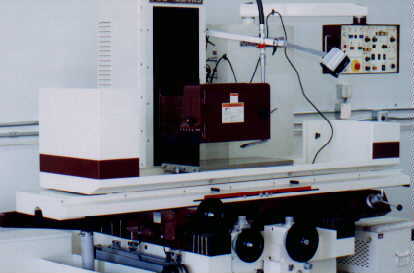

CNC MACHINING & GRINDING

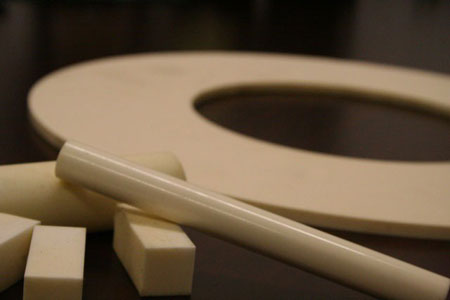

Modern Ceramics excels at precision CNC machining and grinding--our primary method of ceramic component fabrication. We possess 30,000+ sf of CNC grinding and machining capacity. The metal and plastic machining operation is separated from our ceramic grinding equipment. Machining is performed using conventional cutting tools while ceramic grinding requires diamond plated wheels and tools.

CNC Mills

Work envelope: up to 32” x 120”

CNC Turning Centers

Work envelope: up to 25” OD x 48” long

Multiple Manual Lathes and Mills

Flat Grinders

Surface grinders: Plates up to 28” x 125”

Rotary Grinders:Up to 42” diameter

Other Grinding Equipment

Includes:

- Lapping & Polishing Machines

- Honing

- Press Fitting

- Brazing

Support equipment and processing includes:

- Glass Bonding of Ceramics (mainly used to produce ceramic end effectors)

- Laser marking

- Brazing

- Laser Cutting

- Waterjet Cutting

- Slicing

- Clean Room Assembly

- Class 100 Cleaning and Packaging

Clean Room Packaging & Assembly